EMS is intended for improving product quality and business efficiency at aluminium producing companies.

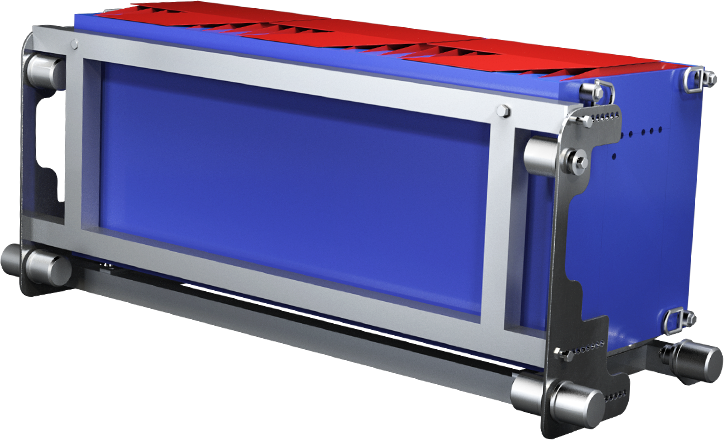

The EMS system is installed on the exterior of the furnace (side or bottom), no physical contact with the melt, stirring takes place through a steel casing and full refractory thickness of the furnace hearth or wall. The unit is very reliable and easy to operate. Payback time on investment of less than one year can be anticipated, but will depend on the application.