Ontecom develops, manufactures and supplies filter boxes and launders, which are distinguished by a flexible combined heating system. Ontecom's filter boxes and launders fully meet the technology of the aluminum alloys preparation and reduce the amount of specific energy consumption per ton of finished product.

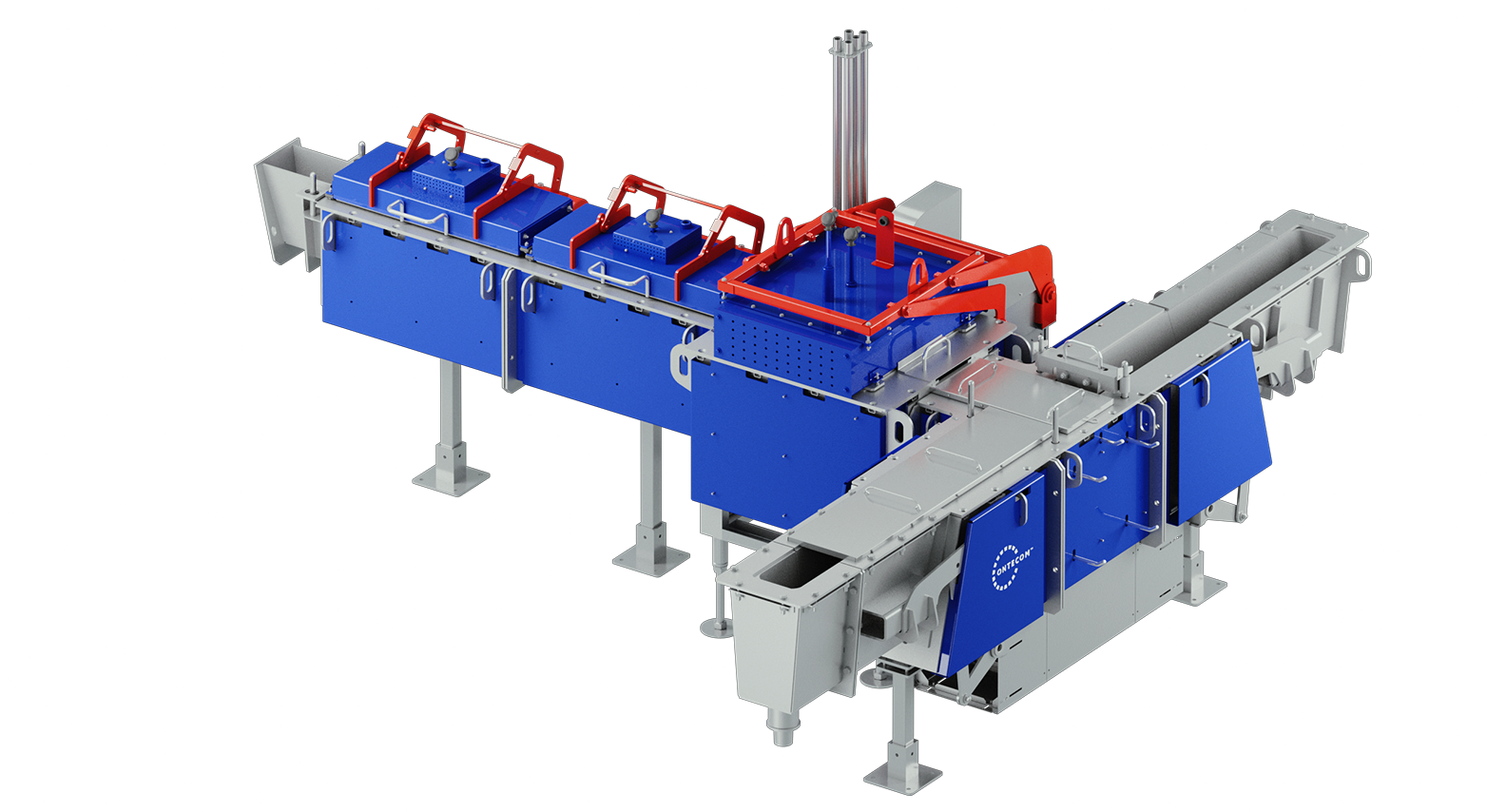

Filter boxes and electrically heated launders

Increase the energy and process efficiency of casting

Structural design

Filter box: straight-through, twin, by-pass and double filtration (two ceramic foam filters one above the other);

Combined heating combines several heat transfer methods and provides the flexibility of process modes;

Launders with partial or full compensation of heat loss, as well as the possibility of heating the melt in some sections;

Control system: PLC and HMI based or w/t the use of PLC.

Ontecom's filter boxes and heated launders provide the following benefits

- Full or partial heat loss reduction at the start and during the casting beliminates the formation of the crust build-up and improves the product quality;

- Convection pre-heating of the ceramic foam filter with a hot air ensures its full use during the entire casting cycle;

- The compensation of heat loss in the launders and the rejection of the melt overheating in the furnace prior to casting allow to reduce the specific energy consumption per ton of finished product.

Filter and launders heating methods:

- Infrared heaters, located in the cover (hinged or cantilever)

- Convection heaters for preheating a porous ceramic foam filter prior to casting

- Embedded heaters, mounted between the refractory and the insulation for heating prior to and during casting.

Advantages of ontecom's filter boxes and launders

The use of different heating methods, depending on the objective:

- radiation;

- convection;

- thermal conductivity.

Available modes:

- heating the refractories prior to casting;

- melt loss compensation;

- heating the melt.

Special design of the filter cover and the launder for the convenience and safety of the operating personnel

Optimum refractory sections and refractory physical properties to minimize heat losses and the capital costs of the customer

Flexible launder heating modes control system with the possibility of power distribution along the length of the launders

The use of low-voltage electric heating elements, safe if a melt leakage happens.

Have a question? Our experts are ready to help you

Sales Department

Tel./fax +7 (391) 219 04 01

E-mail: info@ontecom.com

Engineering Department

Tel./fax +7 (923) 570 83 50

E-mail: goremykin_va@ontecom.com